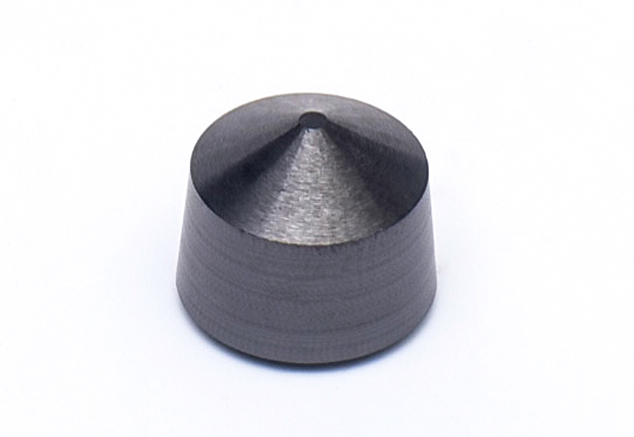

Round bottom blade

Specification of ceramic blade of RECT

| shape | Brand | model | size(mm) | Negative chamfer | |||

| Inscribed circle | thickness | Tool tip radius | 10015 | 20015 | |||

| RCHT03 | RBG16W | 16.00 | 13.00 | 00 | ● | ● |

| RBG20W | 20.00 | 15.00 | 00 | ● | ● | ||

Blade specifications can be customized according to customer requirements

Performance Characteristics of Main Materials of Ceramic Inserts

| Material grade | density(g/cm³) | hardnessHv(Gpa) | Bending strength(Mpa) | fracture toughness(Mpa m1/2) | characteristic | |

| RCHS02 | 3.75 | 20~21 | 600~800 | 6 | Excellent wear resistance, suitable for semi finishing and finishing | |

| RCHS03 | 3.38 | 18~19 | 700~900 | 6.5 | Good impact toughness, suitable for rough and semi finish machining | |

| RCHT03 | 4.85 | 20~22 | 700~900 | 7 | Excellent wear resistance, suitable for semi finishing and finishing | |

Materials with different numbers are made by adding metal binder on the basis of silicon nitride

The RECT ceramic tool has the following characteristics:

❊High hardness and wear resistance, the hardness at room temperature reaches 91~95HRA;

❊High heat resistance, 80% room temperature hardness, bending strength and toughness at 1000 ℃;

❊High chemical stability, small affinity between ceramic and metal, good high-temperature oxidation resistance;

❊With low friction coefficient, the chip is not easy to stick to the knife, and it is not easy to produce chip buildup.

- Prev:没有了!

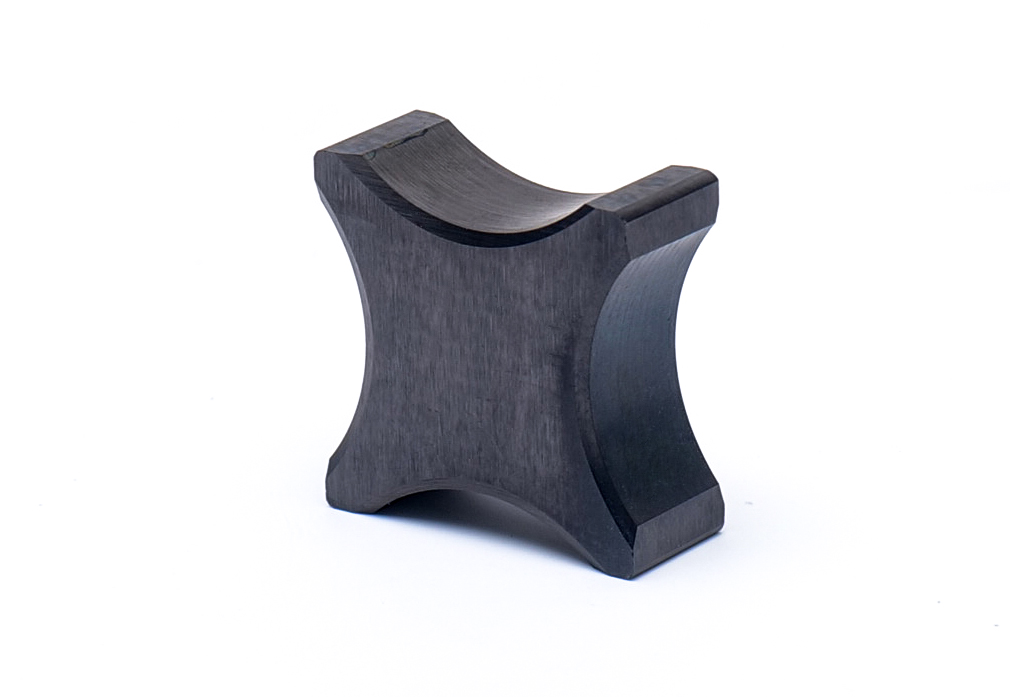

- Next:Bearing chamfering blade