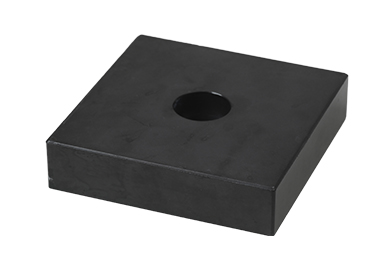

Wear block

Performance Characteristics of Main Materials of Ceramic Wear Parts

| Material Science Brand | density (g/cm³) | hardness Hv(Gpa) | Bending strength (Mpa) | fracture toughness (Mpa m1/2) | Thermal conductivity w/(m.k) | Coefficient of thermal expansion (x10-6/K) | Volume resistivity Ω.cm) | main features | main purpose |

| RCVS01 | 3.20 | 14~16 | 700~1000 | 8 | 20~25 | 3.1 | ≥1014 | Light weight, high strength, high abrasion resistance and impact resistance Good, corrosion resistant, high insulation, self-lubricating | Wear resistant patch |

| RCHS01 | 3.32 | 17~18 | 700~1000 | 7 | 30~35 | 3 | ≥1014 | Wear parts, structural parts | |

| RCHS02 | 3.75 | 20~21 | 600~800 | 6 | 40~45 | 3.5 | <1 | Light weight, high hardness, high wear resistance, corrosion resistance Good high-temperature performance | CNC blade, wire drawing die |

| RCHS03 | 3.38 | 18~19 | 700~900 | 6.5 | 35~40 | 3.2 | ≥108 | CNC blade, wire drawing die | |

| RCHT03 | 4.85 | 20~22 | 700~900 | 7 | - | 7 | 0.01 | High strength, high hardness, high wear resistance and high temperature performance Good, good conductivity | CNC blade, wire drawing die |

The silicon nitride wear-resistant patch series products produced by Ruikete Ceramics can be widely used in the hopper, silo, pipeline and other key parts requiring strong wear-resistance and impact resistance in steel, mining, port, power generation, cement and other industries. They can be combined with aluminum oxide ceramic wear-resistant patches to improve the overall wear-resistance by more than 10 times. The products have been widely used in Xinri Steel, Baosteel and other enterprises。

- Prev:没有了!

- Next:Perforated wear-resistant block